How Detroit's Auto Factories Retooled During WWII

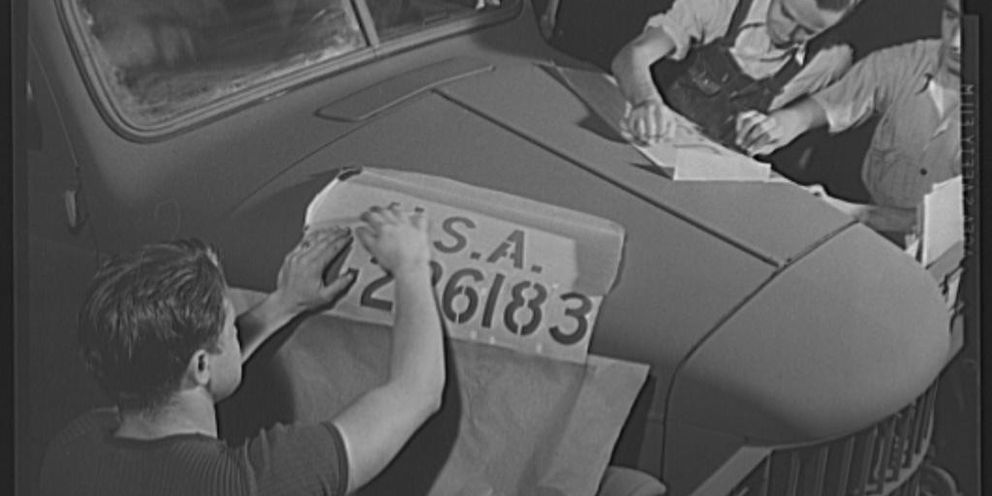

Army truck manufacture (Dodge). Close-up showing men putting stencils in place on the hood of a Dodge Army truck - Library of Congress

Today, Detroit and the surrounding areas in the State of Michigan are now known for being the most prominent towns in the United States for developing and manufacturing vehicles, as they are home to Ford Motors, General Motors, and Stellantis North America. What many people don't know, however, is that the automotive factories in the area made massive transformations during World War II and "retooled" to accommodate the production of all sorts of wartime equipment and vehicles.

How It Started

The official retooling of the auto industry started on January 1, 1942 when the United States Office of Production Management (ultimately renamed the War Production Board) ordered a complete stop to the manufacturing of all automotive parts and automobiles - both passenger and commercial vehicles - unless given special permission by local authorities. Every automaker ceased normal production and only "essential drivers" had access to any available vehicles.

The Automotive Council for War Production, which was geared towards helping everyone in the auto industry as well as defense contracting firms share information, employees, and skills, was formed in April of 1942 and would be instrumental in the success of the retooling.

Conversion. Automobiles to 40 mm. anti-aircraft guns. Chrysler Corporation, Highland Park, Detroit - Library of Congress

What the Retooling Involved and How It Was Advertised

Instead of utilizing materials needed for auto production such as oil, various metals, and rubber, the War Production Board regulated the distribution of such products. These resources were instead used to manufacture wartime equipment including ammunition, helmets, planes, bombs, military tanks, and the classic jeep military vehicles (see automaker-specific developments below).

To accommodate the production transition, factories were swiftly transformed. Various parts and tools were stashed away in storage, while others were recycled to be used in other manufacturing processes. A nationwide speed limit of 35 miles per hour was set and gasoline was strictly regulated and rationed.

Despite a huge shift in manufacturing throughout this time, automakers and oil producers did not stop advertising for themselves, as they would feature the amazing products that they were developing to help war efforts. Also, when the end of the war was nearing, automakers began advertising their upcoming vehicles that would be available once normal vehicle production resumed.

What General Motors Did

Perhaps one of the most famous quotes from WWII was that of GM's former president, William Knutsen, who told top members of the auto industry, "Gentlemen, we must out-build Hitler." He had stepped down from his position at GM when then-president Franklin Roosevelt requested he become the head of military production.

While Knutsen worked his way up to the rank of lieutenant general, GM contributed to wartime efforts by creating various vehicles, most notably the so-called "duck truck." The automaker produced more than 21,000 of these vehicles, which cost almost $11,000 and were 31-feet long and able to carry more than 5,000 pounds. Used mostly during the Normandy Invasion, these vehicles ended up delivering over 5 million tons of supplies throughout the war and were the military's solution to "landing" ships where there were no ports. They became known as vehicles that could "walk on water," as they could be launched from ships and utilize propellers to move through the water before subsequently shifting to all-wheel drive once they reached the ground.

GM also produced tanks at its Cadillac facility, and Oldsmobile factories were generating much-needed artillery rounds while Pontiac engineers manufactured Oerlikon cannons. GM also produced additional items which include, but are not limited to, guns, electric motors, diesel engines, carbines, planes for the Navy, and propellers. Thanks to its leadership and successful vehicles and wartime supplies, GM was the largest military contractor globally when the war was over.

What Ford Did

In 1941, Ford started working on its 56,000-pound B-24 Liberator, which was America's most intense bomber during the war and Ford's first four-engine bomber. The factory that built these was named the Willow Run Bomber Plant and, within 4 years, had produced more than 8,500 of these bombers. On average, a full B-24 bomber was eventually produced within just one hour. While many military and aviation experts initially expressed great skepticism that these would succeed, B-24s are now the most mass-produced aircraft in the U.S. military.

Ford also built so-called "blitz buggies," which were mass produced, four-wheel drive vehicles that weighed under 2,175 pounds and could carry at least 625 pounds. The purpose of these vehicles, which we now call "jeeps," were built to carry heavy loads while also having the ability to operate on rough terrains. Of course, these types of vehicles are still used today albeit now having more advanced features and upgraded parts.

What Chrysler Did

Chrysler, which was another one of the top Detroit automakers at the time, was asked directly by Knutsen to build tanks. The automaker had never produced a tank, but swiftly began building its Detroit Arsenal Tank Plant and was miraculously able to build the first Chrysler M3 tank before the factory was even completed. M4 Sherman tanks were introduced after that and welded together five six-cylinder engines recycled from the automaker's Royal and Windsor passenger cars. This process, in turn, gave these tanks an impressive 30-cylinder motor.

Despite hesitance at first because Chrysler had never built a tank before, the automaker ended up producing more tanks than Nazi Germany did throughout the entire war.

Chrysler engineers also played a large role in developing the atomic bomb, despite not knowing what they were actually working on. Known as Project X-100, Chrysler had turned a department store into a production facility that was monitored by agents from the Federal Bureau of Investigation at all times. Only Chrysler executives knew the reason why the engineers were developing metal containers shaped like a cylinder that would become known as diffusers, but these diffusers became so successful that they were used for another 40 years.

Conclusion

At one point, President Roosevelt deemed Detroit the "Arsenal of Democracy" thanks to auto companies being able to retool and mass produce equipment and vehicles despite a massive housing shortage due to so many engineers and employees moving into the area and other issues like inadequate highways and overall nationwide rationing of food and goods.

Together, it is estimated that Detroit companies produced over 90% of military helmets and manufactured over 2.6 million military vehicles before the war was over.

While the rivalry between the so-called "Big 3" automakers in Detroit is quite intense today in terms of producing passenger and commercial vehicles, the retooling of the top automaker's plants during WWII was a testament to their dedication to working together with the U.S. military to beat Hitler (and his cronies) and win the war. In just a few years, the auto factories had created some of the swiftest and most effective production changes in history - and it paid off.

Updated